Services

RCD Testing

Residual Current Device Testing

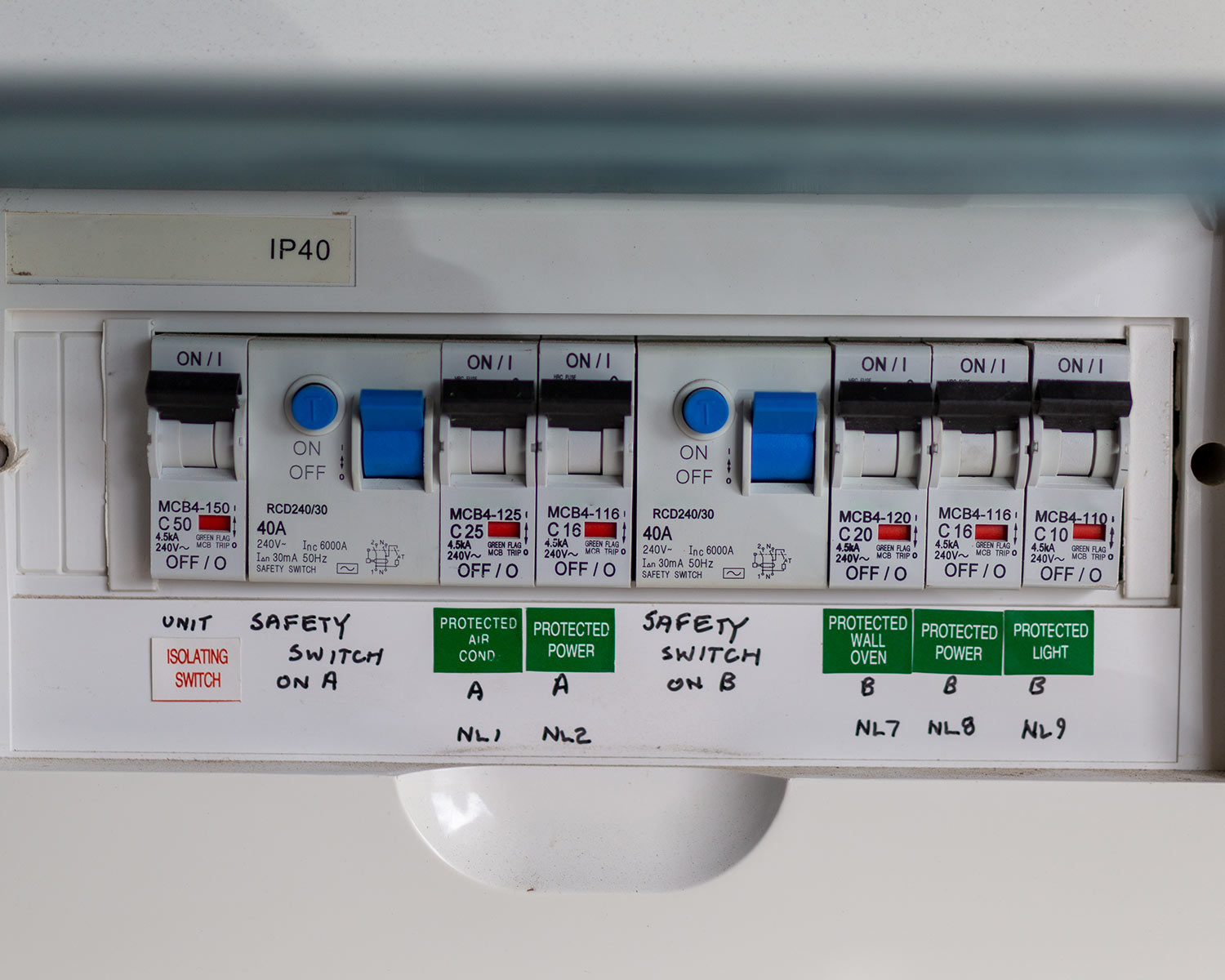

A Residual Current Device (RCD) is also commonly called a “safety switch.” These RCDs are essential safety devices, and they offer high levels of protection from fires and electric shock. Normally an RCD would be found at the switchboard, but they can also be used portably.

If you are not sure whether you have sufficient RCDs installed in your workplace, it is time to call Rotric. We can survey your workplace and determine if it complies with the latest safety standards or if changes need to be made in order to create a proper environment for your workers.

Because an RCD is such a vital and important part of the electric circuit, it is important that it be tested following proper procedures, on the right schedule of frequency, and by a competent professional. That can provide a higher level of safety, but it also gives peace of mind.

Let’s talk about your next project

Contact our friendly team at Rotric for your obligation free quote.